A recent survey by the online space magazine Austronautinews, explains the strategies of the French Ariane and ESA, the European Space Agency, for the use of LNG to replace hydrogen in the new engines of the "Prometheus" series.

Ariane joins the Italian Avio Aerospazio and the US Space X of Elon Musk and Blue Origin of Jeff Bezos, in the use of liquid methane as fuel and liquid oxygen as oxidizer. The use of methane allows the reuse of spacecraft, significantly reducing the costs of each mission.

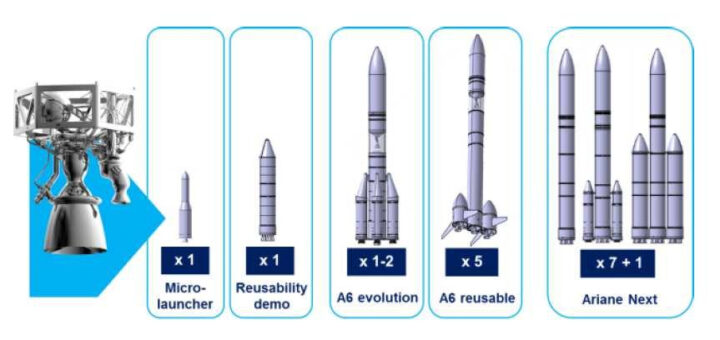

As reported by the magazine, Ariane Next is the name of the new family of reusable launchers, based on the new Prometheus (Precursor Reusable Oxygen METHane cost Effective propUlsion System) propulsion system, born from the collaboration of the French space agency CNES with Ariane Group.

Prometheus in 2016 joined the new launcher development program (FLPP) of the European Space Agency ESA, with Germany, Italy, Belgium, Sweden and Switzerland joining France for the realization.

The final goal of Ariane Next is the cost: each unit should cost no more than 1 million euros (counting a production of 50 units per year), with a saving of 10 times compared to the current "Vulcain 2" engine used on the first stage of Ariane 5.

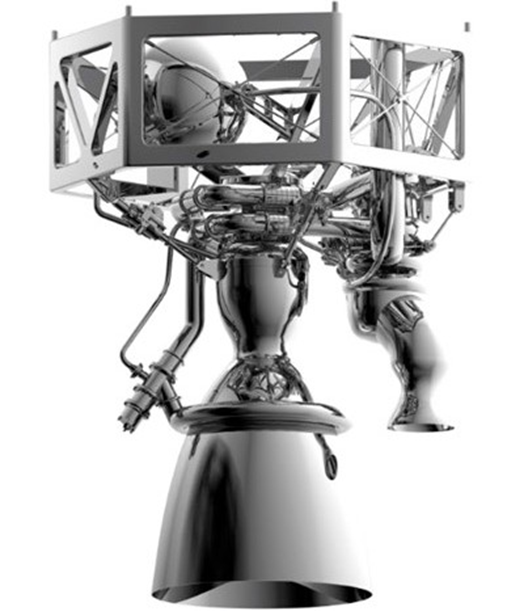

The use of liquid methane instead of liquid hydrogen leads to a small decrease in thrust power, but allows a significant simplification of the global architecture and a reduction in the number of components.

The maximum developed power of the new engine will be 100 tons (1000 kN), with the possibility to adjust the thrust between 30% and 110%, which offers a considerable control capacity as needed. It is designed to be used on both the first and second stage and, having the capacity to be restarted several times, it can also be used on the upper stages.

The project is progressing very quickly and is currently undergoing "Manufacturing Readiness Reviews", the revision that will start the realization of the final components. In the last two years, for demonstration purposes and to be able to conduct mechanical tests, many parts have been produced using 3D printing.

By the end of the year the first complete engine will be ready to start the ignition tests in Lampoldshausen, Germany (already passed by Avio Aerospazio in the USA).

Source: Astronautinews.com

EN

EN  it

it